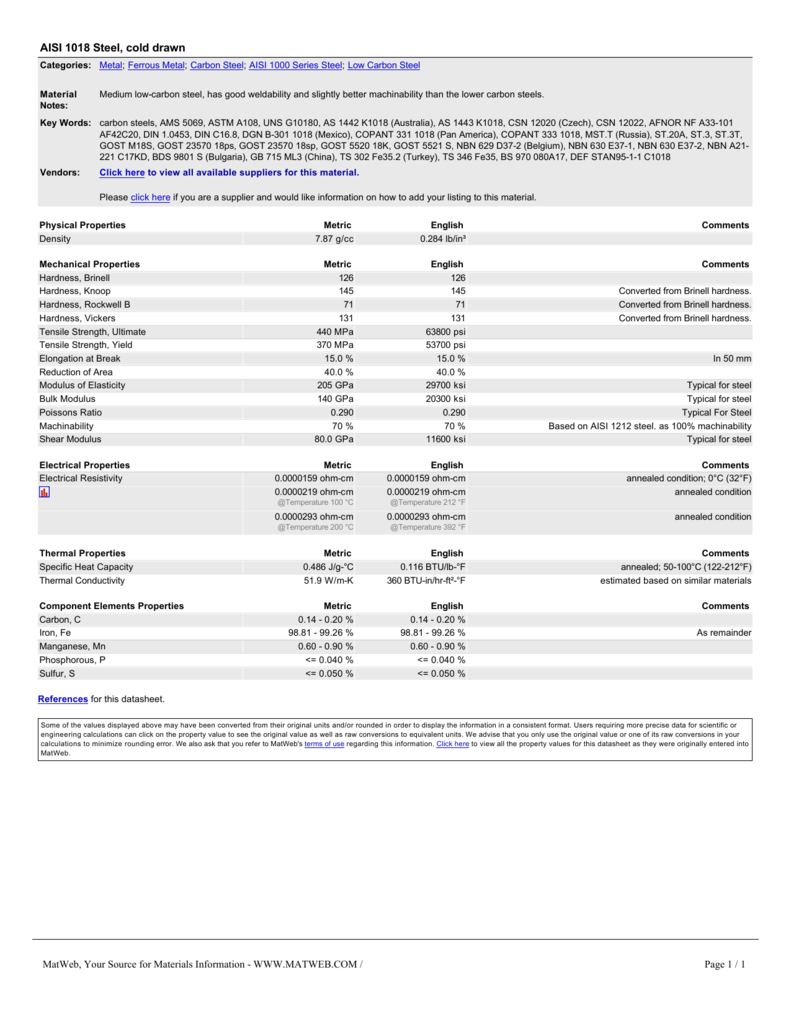

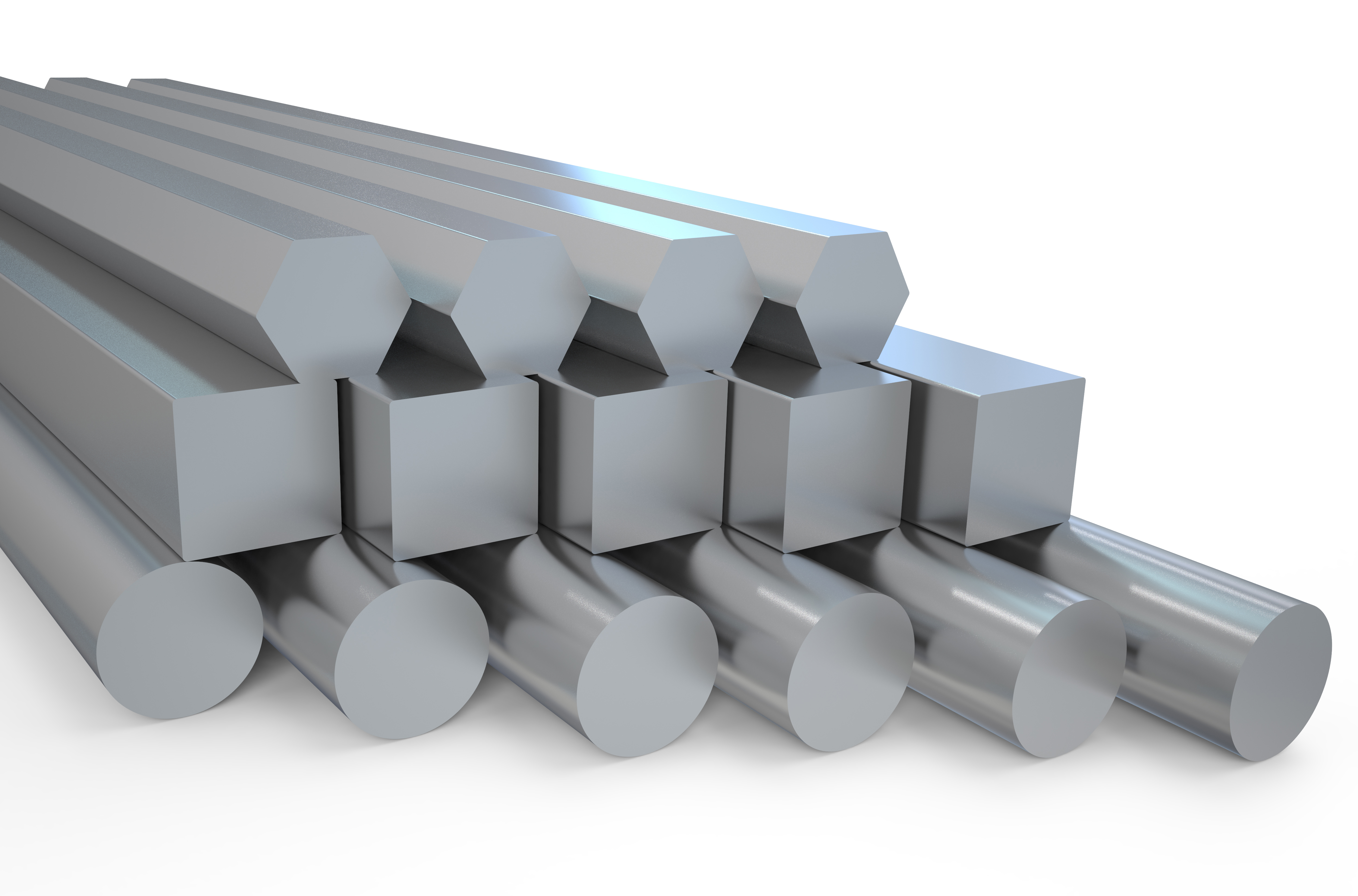

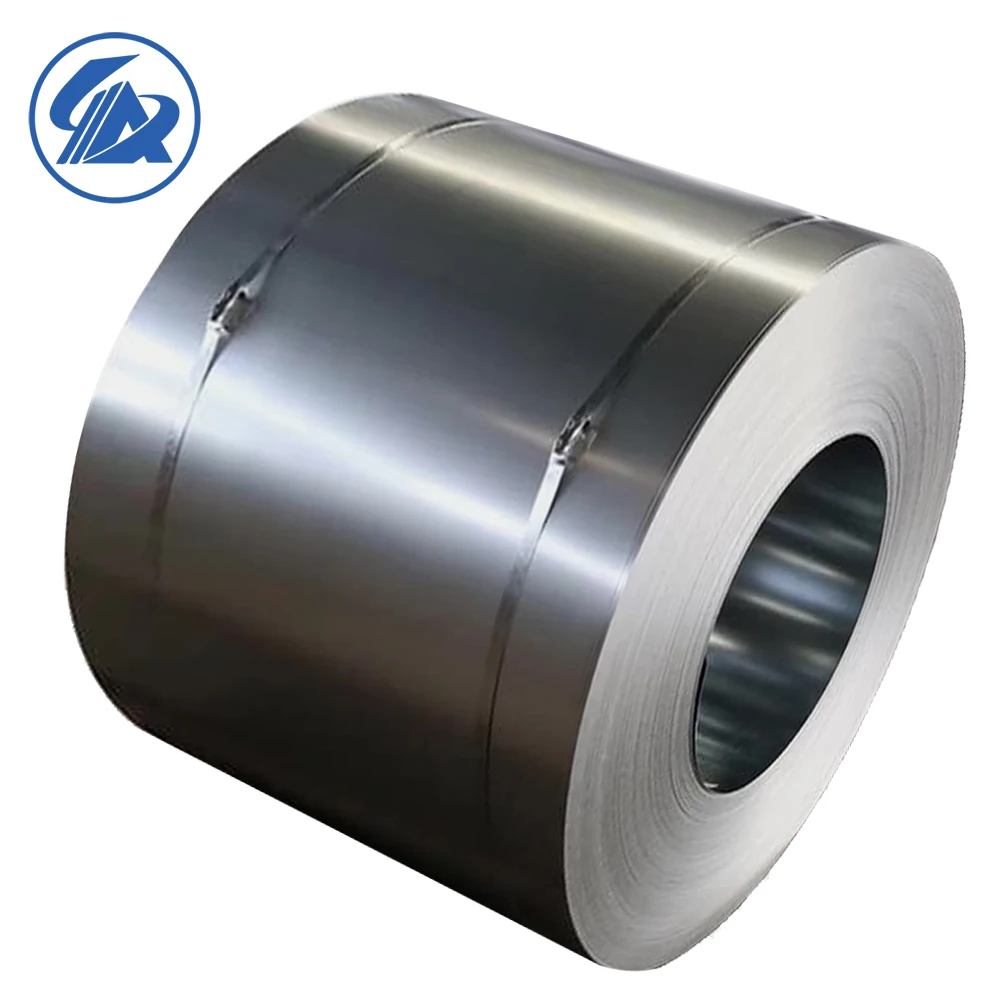

SAEAISI 1018 steel is a carbon (nonalloy) steel formulated for primary forming into wrought products 1018 is the designation in both the SAE and AISI systems for this material G is the UNS number The properties of SAEAISI 1018 steel include two common variationsThermal Properties Metric English Comments 6SHFLILFHDW&DSDFLW\ 0486 J/g & 0116 BTU/lb ) annealed;Manufacturer of C1018 STEELCOLD ROLLED FLAT BAR available in a number of sizes to suit your application needs, request a quote or place an order with Metal Supermarkets today In addition to improvement of mechanical properties, the cold rolling produces steel plate/sheet of the desired physical dimensions Steel may be annealed subsequent

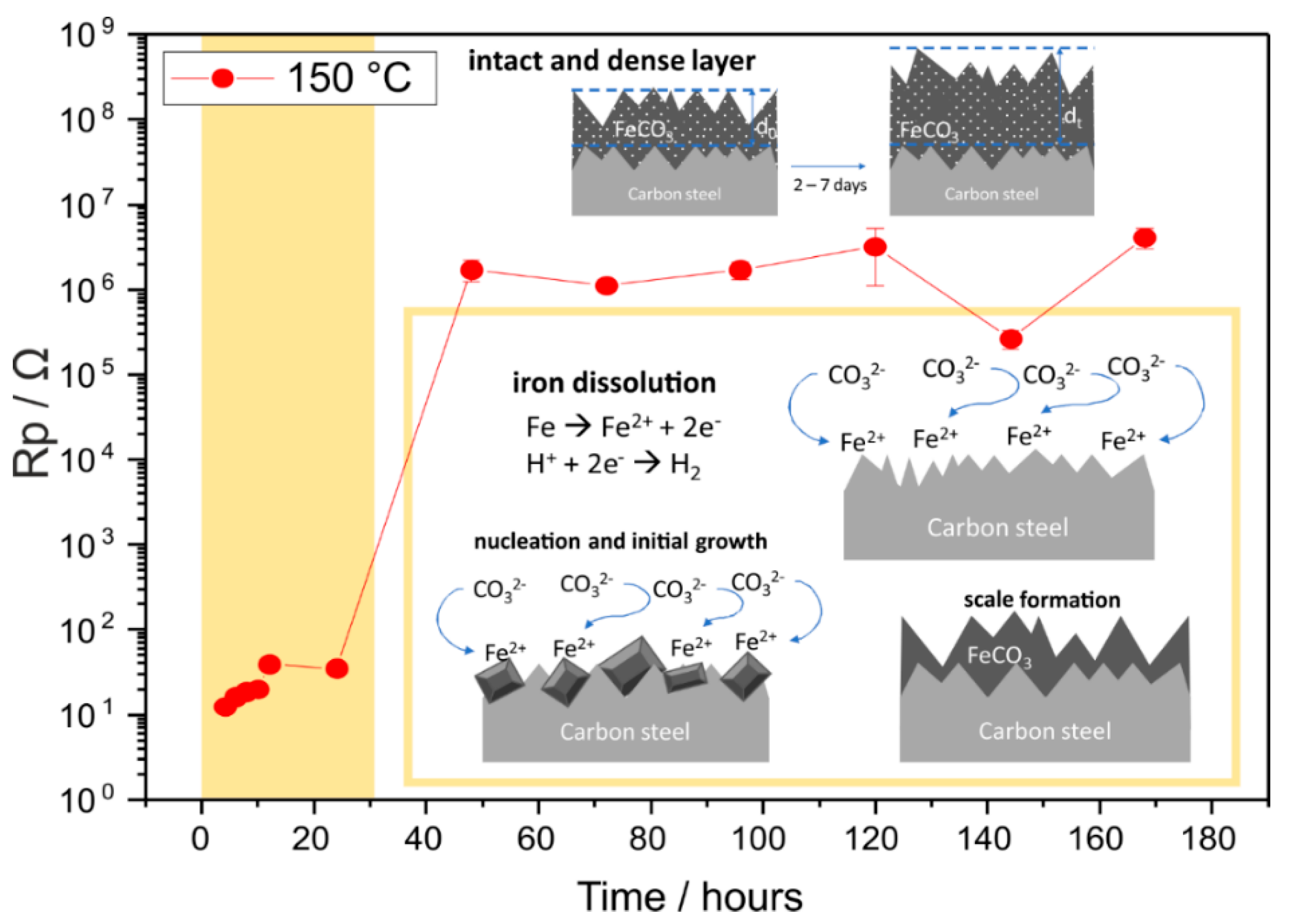

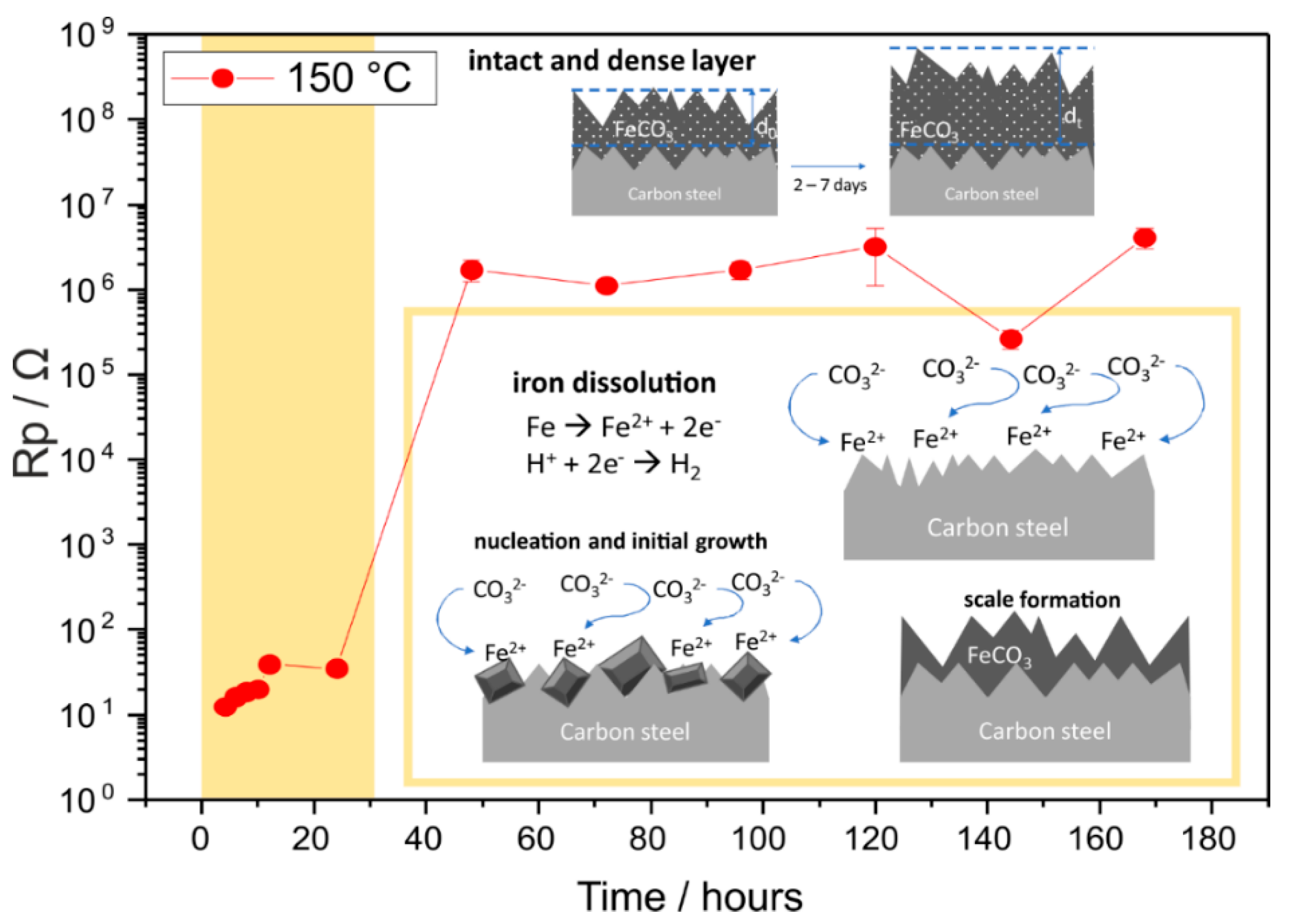

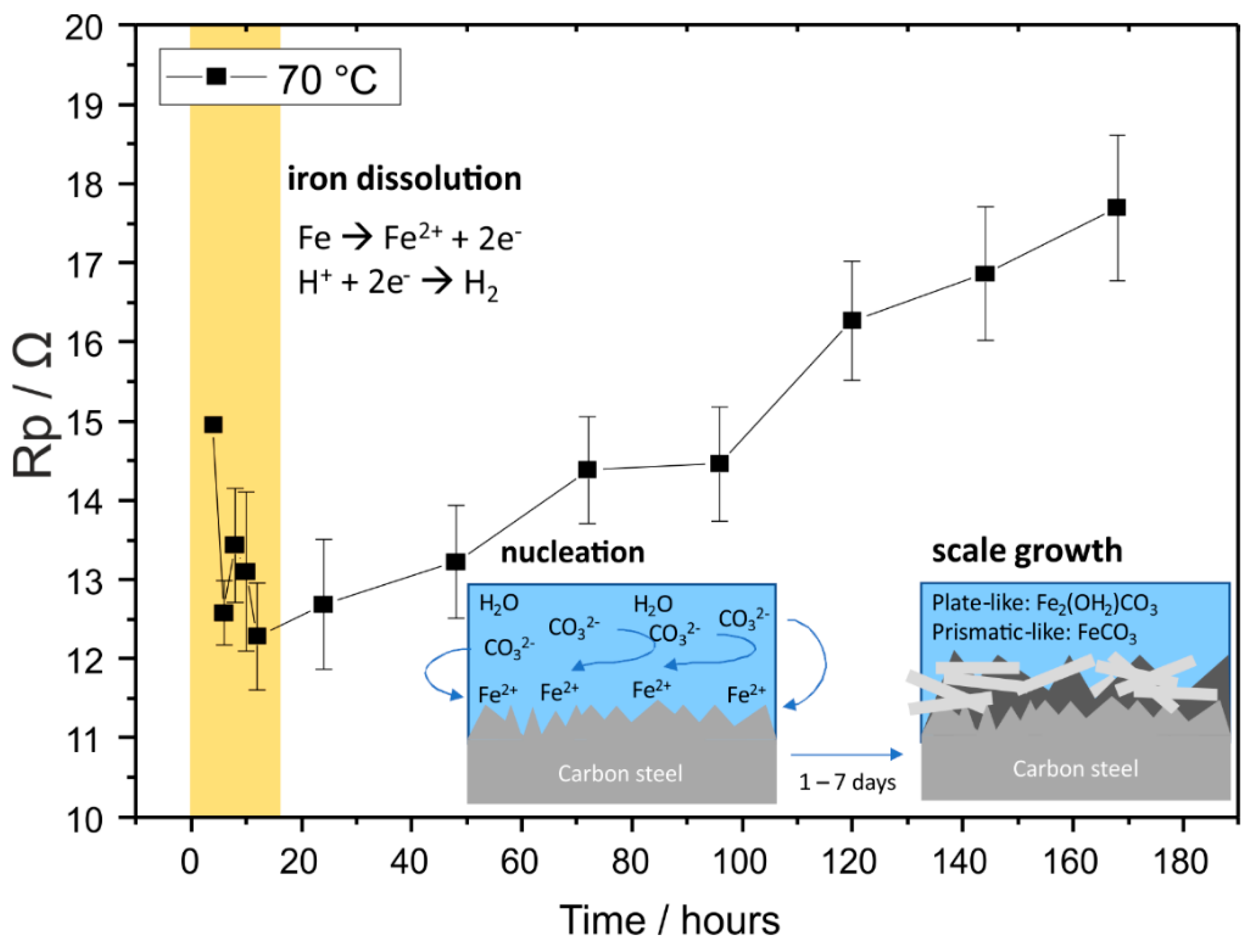

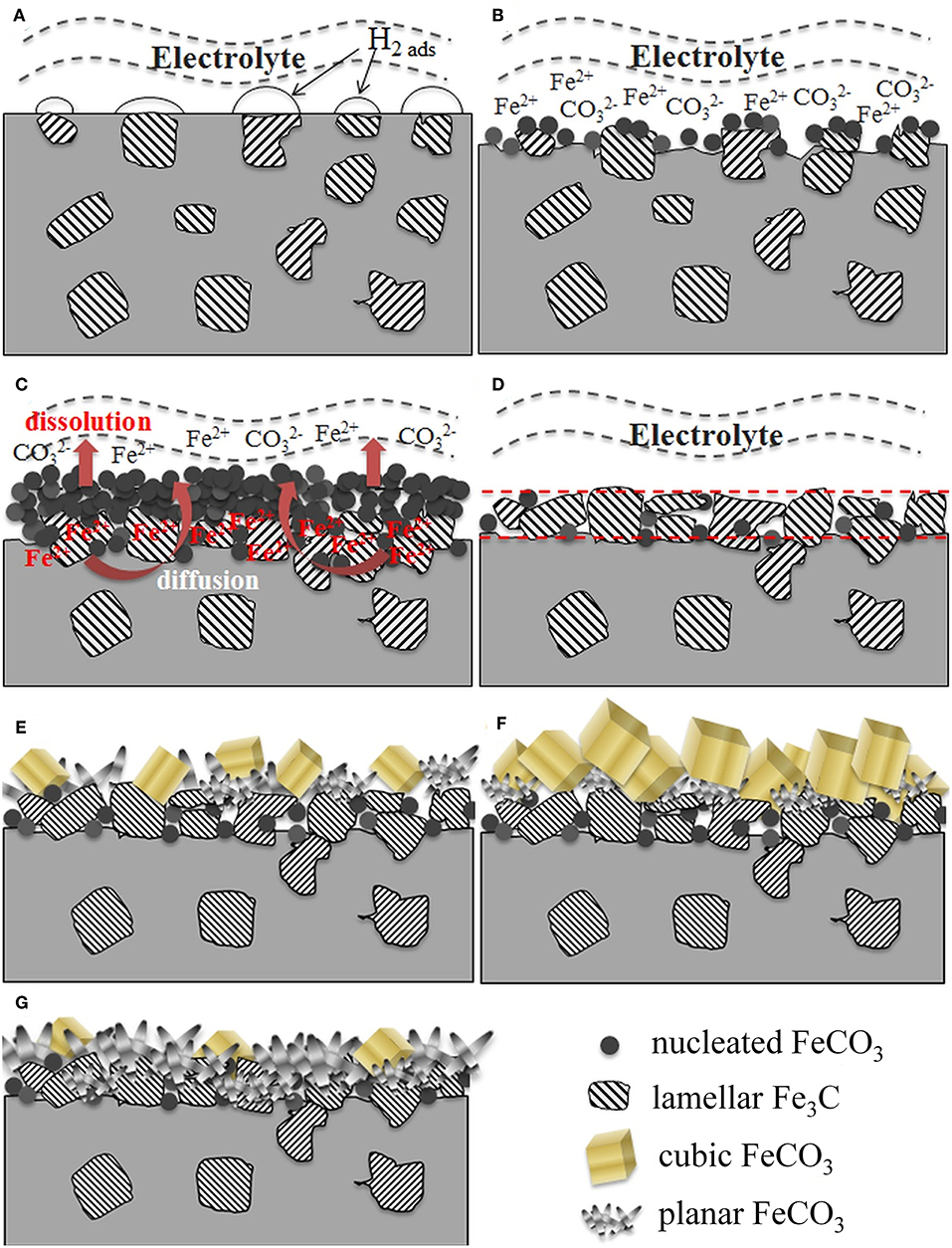

Materials Free Full Text Corrosion Of Carbon Steel In Artificial Geothermal Brine Influence Of Carbon Dioxide At 70 C And 150 C Html

C1018 steel mechanical properties

C1018 steel mechanical properties- AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductilityChemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better properties Typically used in pins, rods, shafts, spindles, and sprockets Common Trade Names UNS G, AISI 1018, C1018, Marshallcrat Other Resources Safety Data Sheet Weight Calculator Mill Test Reports

Iso Shear Connector Weld Stud Steel Shear Stud Building Material C1018 Buy Iso Shear Connector Weld Stud Steel Shear Stud Product On Alibaba Com

A513 Carbon Steel Properties A513 carbon steel mechanical tubing is only manufactured from materials that match the criteria for carbon steel The chemical composition for A513 is mostly iron with added carbon, manganese, phosphorus, silicon, and silver Check out the chart below for exact A513 carbon steel chemical specificationsHere are the physical and chemical properties of the 1008/1010 carbon steel that we regularly stock Cold Rolled 1008/1010 Steel Physical Properties ASTM A1008/1010 Temper Designation Alloy Dead Soft DS Type B 1008Typical for steel Machinability 7000% 7000% Based on AISI 1212 steel as 100% machinability Shear Modulus 780 GPa

Carbon steel is a steel with carbon content from about 005% up to 38% by weight The definition of carbon steel from the American Iron and Steel Institute (AISI) states no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect;Grade Summary C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility

Cold Rolled 1018 vs A572 gr 50 By GSCrisi Date 1513 Tim, I've got the ASTM Book before me and A572 is defined as "High strength, low alloy, columbiumvanadium steels of structural quality" On the other hand, SAE 1018 is a low carbon steel with a carbon content of 018 %, with no alloying element whatsoeverSteel Grade AISI C1018 AISI C1018 This grade is produced in an electric arc or basic oxygen furnace and contains the greatest ductility of all carbon steel grades stocked in service centers Stocked in cold finished bars in a variety of shapes and sizes, its relatively low carbon, manganese, phosphorus and sulfur content make it a naturalSteel GradesAISI 1018 Chemical information,Mechanical properties Physical properties, Mechanical properties, Heat treatment, and Micro structure AISI 1018 Physical Properties Tensile strength σb/MPa Yield Strength 23 σ 02 ≥/MPa Elongation 65 δ5≥ (%) ψ ψ≥ (%) Akv Akv≥/J HBS HRC 30 AISI 1018 Mechanical Properties

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

Q Tbn And9gcsvhuusekokgta9xwuc8skb9fivh5ob3kfexc5rphnjw8vtaeob Usqp Cau

1018 cold finish carbon steel is a general purpose, low carbon steel with a higher manganese content that other low carbon grades The higher manganese content allows 1018 to achieve a harder and more uniform case It also possesses greater mechanical properties and machining than similar low carbon grades1018 Carbon Steel Technical Data 1018 is among the most commonly available grades available in the world It is widely available in cold finished rounds, squares, flat bar and hexagons Despite its unimpressive mechanical properties, the alloy is easily formed, machined, welded and fabricatedThermal Properties Metric English Comments;

1

C1018 Aisi 1018 Cold Drawn Carbon Steel Square Flats Hex Bar China Cold Drawn Steel Bar Hexagonal Steel Bar Made In China Com

C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform caseBecause mechanical properties will change with different manufacturing processes, we'll use numbers for cold drawn 1018 grade steel 1018 comes in many different sizes and shapes based on the purpose and use for the steel including squares, hexagons, rounds and flats 10 Steel Hot rolled SAEAISI 1018 is SAEAISI 1018 steel in the hot worked condition The graph bars on the material properties cards below compare hot rolled SAEAISI 1018 to wrought carbon or nonalloy steels (top), all iron alloys (middle), and the entire database (bottom) A full bar means this is the highest value in the relevant set

Carbon Steel Aisi 1018 Bright Bars Aisi 1018 Cs Round Bar Carbon Steel Aisi 1018 Flat Bars Manufacturer Supplier Stockists

Pdf Inspection Of An End Quenched Plain Steel Jominy Bar With Photothermal Radiometric Techniques

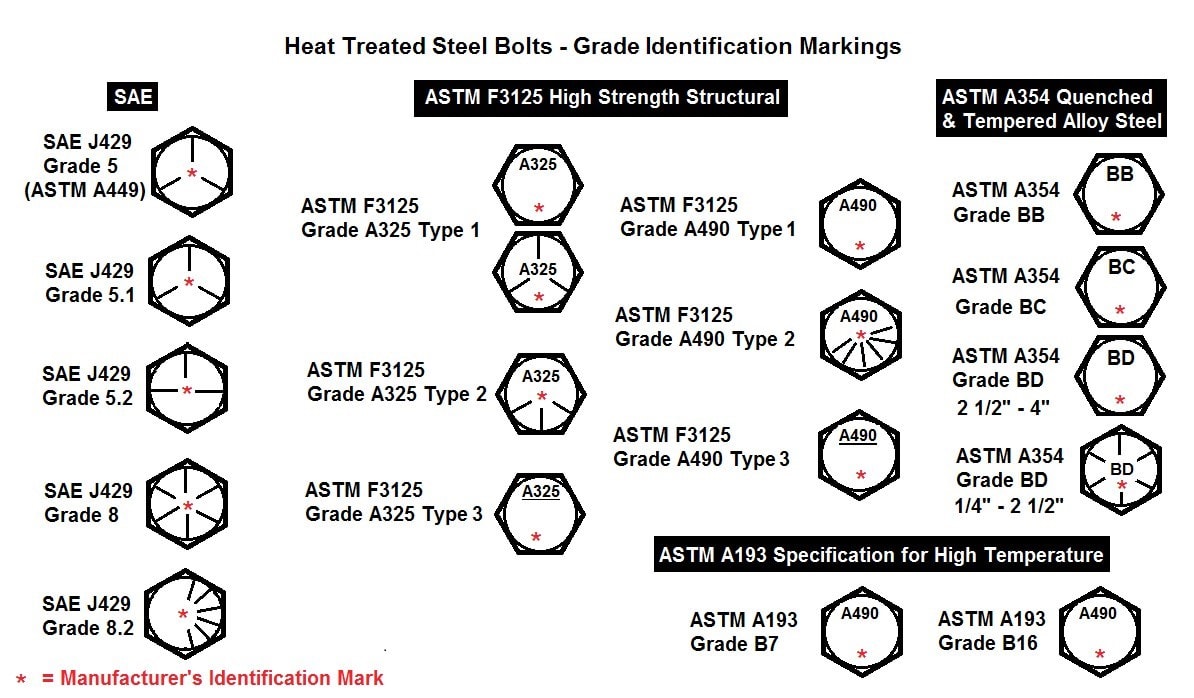

C1018 Cold Finish Round, is a rolled steel product with close dimensional accuracy, smooth surface finish, and increased mechanical properties and machinability C1018 Cold Finish Round is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bending Mechanical Properties of Common Stainless Steel Fasteners in Accordance with ASTM F593 Nominal Dia Tensile Strength Min Yield Strength (in) (psi) Min Max (psi) 1 100,000 150,000 85,000 140,000 2 100,000 150,000 85,000 140,000 C32 65,000 B80 C32 45,000 Grade Identification Marking (316, 316L) CW 1/4 5/8 3/4 1 1/2 B95 65,000 B801018 Cold Roll Steel C1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 With higher manganese, 1018 is better steel for carburized parts, since it produces a harder and more uniform case It also has higher mechanical properties

Www Encoremetals Com Assets Pdf Encore metals product manual 16 final Pdf

2

Mechanical Properties (following values are average and are representative) Commercial Drawing Tensile Strength (psi) 3850,000 3646,000 Yield Point (psi) 2330,000 Elongation (% in 2") 3542 3843 Weldability Yes Forming Yes C1018 Cold Finished Bar A low carbon steel with medium manganese contentChemical Composition The chemical features of 1008 and 1018 steel are the following 1008 1018 Carbon, C 010% Max 018% Manganese, Mn %AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and better machinability Cold drawing increases tensile strength, yield strength, torsional strength, surface hardness and wear resistance, but reduces ductility ASTM AISI SAE 1018 hot rolled steel is also known as 1018 HR, and has good

Studies On Spin Arc Welding Process On The Behavior Of C1018 Plates An Insight Into Mechanical And Metallurgical Transformation Iopscience

Www Asminternational Org Documents g Sample Pdf

E 1/3 /ρ 001 01 1 10 100 0001 001 01 1 10 100 1000 Density, ρ (g/cm³) Elastic modulus, E (GPa) ASTM 9 Grade 1018 Polymer Metal Composite Ceramic Glass Biological Material Min mass design Rod Min mass design Beam Min mass design ShellAISI 1081 grade has low carbon steel content Up to 025% carbon You can buy all types of AISI 1018 Nuts, AISI 1018 Bolts, AISI 1018 Screws, AISI 1018 Washers for ideal connection & captious applications To get a free quote and a quick response call us AISI C1010 and AISI C1018 are two hot rolled steels that are very similar They are both low carbon In fact, the only noticeable difference between their chemical compositions is their carbon content C1010 is 008% to 013% carbon by weight and C1018 is

2

Dspace Mit Edu Bitstream Handle 1721 1 Mit Pdf Sequence 1 Isallowed Y

Steel Grades1018 Chemical information,Mechanical properties Physical properties, Mechanical properties, Heat treatment, and Micro structure Cu≤02% 1018 Physical Properties Tensile strength σb/MPa Yield Strength 23 σ 02 ≥/MPa Elongation 65 δ5≥ (%) ψ ψ≥ (%) Akv Akv≥/J HBS HRC 30 1018 Mechanical PropertiesASTM SAE AISI 1018 Carbon Steel Chemical CompositionHardness (HB) 197 25 carburized at 925°C, cooled, reheated to 775°C, water quenched, tempered at 175°C, core properties (round bar (1932 mm)) more

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Astm A36 Structural Steel Properties Nm500 Steel Stocklist Exporter

CTE, linear 115 µm/m°C @Temperature 0 °C 639 µin/in°F @Temperature 680 °F Typical steel 122 µm/m°C @Temperature 0000 300 °C 678 µin/in°F @Temperature 3 572 °F Typical for steel 139 µm/m°C @Temperature 0000 500 °C 772 µin/in°F @Temperature 35 psi Elongation at Break 35% 35% In 50 mm Reduction of AreaAlloy 1018 is the most commonly available of the coldrolled steels It is generally available in round rod, square bar, and rectangle bar It has a good combination of all of the typical traits of steel strength, some ductility, and comparative ease of machining Chemically, it is very similar to A36 Hot Rolled steel, but the cold rolling process creates a better surface finish and better properties

Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 560 3179 Rep Rep1 Type Pdf

Eml2322l Materials And Material Selection

50 & ) 7KHUPDO&RQGXFWLYLW\ 519 W/m K 360 BTU in/hr ftð ) estimated based on similar materials1018 Cold Finished Most cold finished bars are produced by cold drawing oversize hot rolled bars through a die The cold reduction of the bar results in significantly improved mechanical properties, with a smooth surface finish to close tolerancesAISI 1018 mild/low carbon steel offers a good balance of toughness, strength and ductility AISI 1018 hot rolled steel has significant mechanical properties, improved machining characteristics and has a high Brinell hardness measure Specific manufacturing controls are used for surface preparation, chemical composition, rolling and heating processes

Carbon Steel Corrosion A Review Of Key Surface Properties And Characterization Methods Rsc Advances Rsc Publishing Doi 10 1039 C6rag

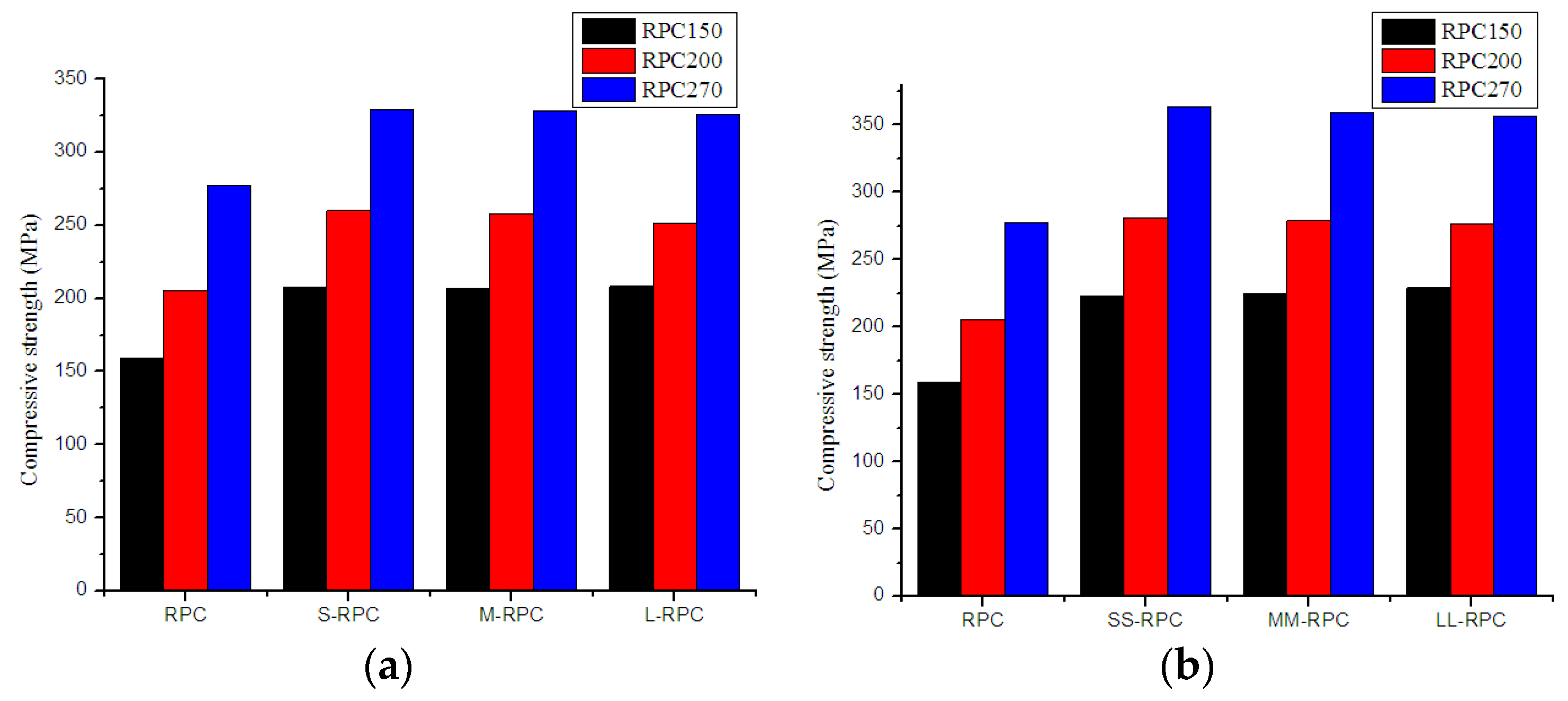

Materials Free Full Text Investigation Of The Match Relation Between Steel Fiber And High Strength Concrete Matrix In Reactive Powder Concrete Html

ASTM A36 is the most commonly used mild and hotrolled steel It has excellent welding properties and is suitable for grinding, punching, tapping, drilling and machining processes Yield strength of ASTM A36 is less than that of cold roll C1018, thus enabling ASTM A36 to bend more readily than C1018C1018 Cold Finish Hexagon, is a rolled steel product with close dimensional accuracy, smooth surface finish, and increased mechanical properties and machinability C1018 Cold Finish Hexagon is a general purpose low carbon steel with good case hardening qualities and is especially suited for cold forming and bendingC1018 is a general purpose low carbon steel with good case hardening qualities It has a higher manganese content than certain other low carbon grades, such as 10 Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case

1

Pdf Microstructure And Mechanical Properties Of Cold Rolled Aisi 1018 Low Carbon Steel

With higher manganese, C1018 is better steel for carburized parts since it produces a harder and more uniform case It also has higher mechanical properties and better machinability due to the cold drawing process Most C1018 is produced by cold drawing In this process, oversized hot rolled bars, which have been cleaned of scale, are drawnPsi Tensile Strength, Yield 370 MPa psi Elongation at Break 15 % 15 % In 50 mm Reduction of Area It is usually used as carburized steel Since most of the 1018 carbon steel is produced by cold drawing, this cold rolled steel is called C1018 (1018 cold rolled steel) AISI C1018 steel (1018 CRS) has good weldability, surface hardening quality, higher mechanical properties and Get Price;

2

Www Skyshop Com Au Metals Pdf

All SAE 1100 series steels are rated on the basis for 010 max silicon or coarse grain melting practice The mechanical properties shown are expected minimums for the sizes ranging from 3/4" to 11/4" REF SAE J1397 Rev May 1992 Alloy Steels SAE No 4037 86 8630 4130 4140 Machinability Rating 70 65 70 70 65 Condition Annealed & Cold Drawn32 Mechanical Properties of Structural Steel at High Temper ature 47 Fig 37 Ultimate strength reduction factor of fire resistant steel (with permission from ASCE) Temperature ( ) The bottomline is that the chemistry of AISI 1018 alone does not ensure the mechanical properties are the same as ASTM A108 You can not substitute an AISI steel for a steel that meets an ASTM specification To do so can have unexpected ramifications You can be in violation of the applicable welding standard or contract and it can endanger

1018 Cold Roll Bearing Quality Alcobra Metals

China Screw Wire C1018 Cold Heading Quality Saip Annealed Phosphating Drawn Steel Wire China Wire Rod Sae1018

SAE AISI 5160 Steel, High Carbon 5160 Spring Steel Properties, Composition AISI 5160 Steel AISI 5160 steel, also known as 5160 spring steel, is a high carbon chromium alloy (maximum carbon content 061%, chromium content 09%) AISI SAE 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is

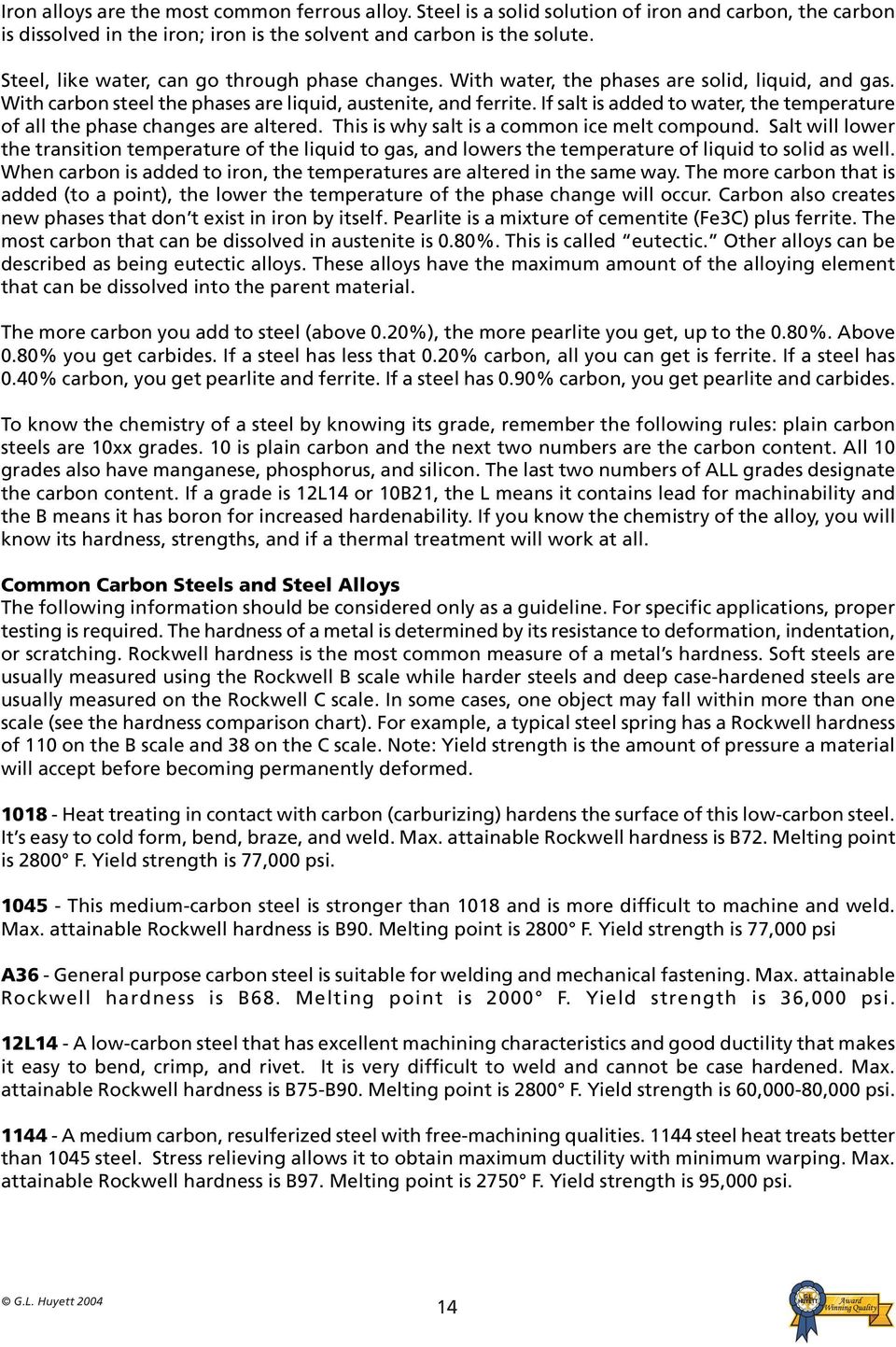

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Cold Finish Astm 108 0 125 Thickness 0 25 Width 84 Length Onlinemetals Industrial Scientific

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Amazon Com 1018 Cold Roll Carbon Steel Rectangular Bar Unpolished Mill Finish Astm 108 0 25 Thickness 1 Width 84 Length Onlinemetals Industrial Scientific

Practical Machinist Largest Manufacturing Technology Forum On The Web

Materials Free Full Text Corrosion Of Carbon Steel In Artificial Geothermal Brine Influence Of Carbon Dioxide At 70 C And 150 C Html

Http Eprints Whiterose Ac Uk 37 Paper2 Pdf

Ftp Ftp Iks Jena De Pub Mitarb Lutz Standards Dstan 01 008 Pdf

Carbon Steel Bars Cold Finished Alro Steel Corporation Pages 1 18 Flip Pdf Download Fliphtml5

7 Things To Consider When Choosing A Carbon Steel Grade

Order 0 125 Mild Steel Round Bar 1018 Cold Finish Online Diameter 1 8

Astm A36 Mildlow Carbon Steel Steel Strength Of Materials

Design With Steel Dimensions Properties Handbook By Steel Tube Issuu

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

A Guide To Carbon Steel Grades Plus A Chart

Dspace Mit Edu Bitstream Handle 1721 1 Mit Pdf Sequence 1 Isallowed Y

1

Dynamic Mechanical Properties Of Self Compacting Rubberized Concrete Under High Strain Rates Journal Of Materials In Civil Engineering Vol 33 No 2

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

Aisi 1018 Steel Cold Drawn

2

Pdf Correlation Of Microstructure And Mechanical Properties Of Metal Big Area Additive Manufacturing

Carbon Steel Corrosion A Review Of Key Surface Properties And Characterization Methods Rsc Advances Rsc Publishing Doi 10 1039 C6rag

Dlscrib Com Download Handbook Of Codes 5ac548dae2b6f5db258c3074 Pdf

In Stock Wholesale Pickled Oiled A 36 Steel Angle

A 36 Carbon Steel Carbon Hot Rolled Steel A 36 Steel Channel Angle Tee A 36 Structural Steel

Grade Guide Aisi 4140 Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

Pdf Example Long Laboratory Report Mechanical Properties Of 1018 Steel In Tension Semantic Scholar

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

A36 Properties Pdf Steel Strength Of Materials

2

Http Www Uwyo Edu Ceas Resources Current Students Classes Meref Example Long Report Pdf

Engineering Handbook By Huyett By Rmc Process Controls Filtration Inc Issuu

Pdf Experimental Investigation Of Mechanical Properties Of Cold Drawn Aisi 1018 Steel At High Temperature Steady State Conditions

Core Ac Uk Download Pdf Pdf

1018 Steel Properties

Steel Grade Aisi C1018 Richmond Steel Canada

Galvanized Carbon Steel Keeps You Safe In The Rain Ulbrich

Materials Free Full Text Corrosion Of Carbon Steel In Artificial Geothermal Brine Influence Of Carbon Dioxide At 70 C And 150 C Html

Aisi 1018 Carbon Steel Uns G Pdf Txt

Weldability Stafford Manufacturing Corp

Grades Of Hot Rolled Steel Metal Supermarkets Steel Aluminum Stainless Hot Rolled Cold Rolled Alloy Carbon Galvanized Brass Bronze Copper

Quality Cut To Size Cold Rolled Mild Steel Hexagons Supplier In Los Angeles Ca Usa Bobco Metals

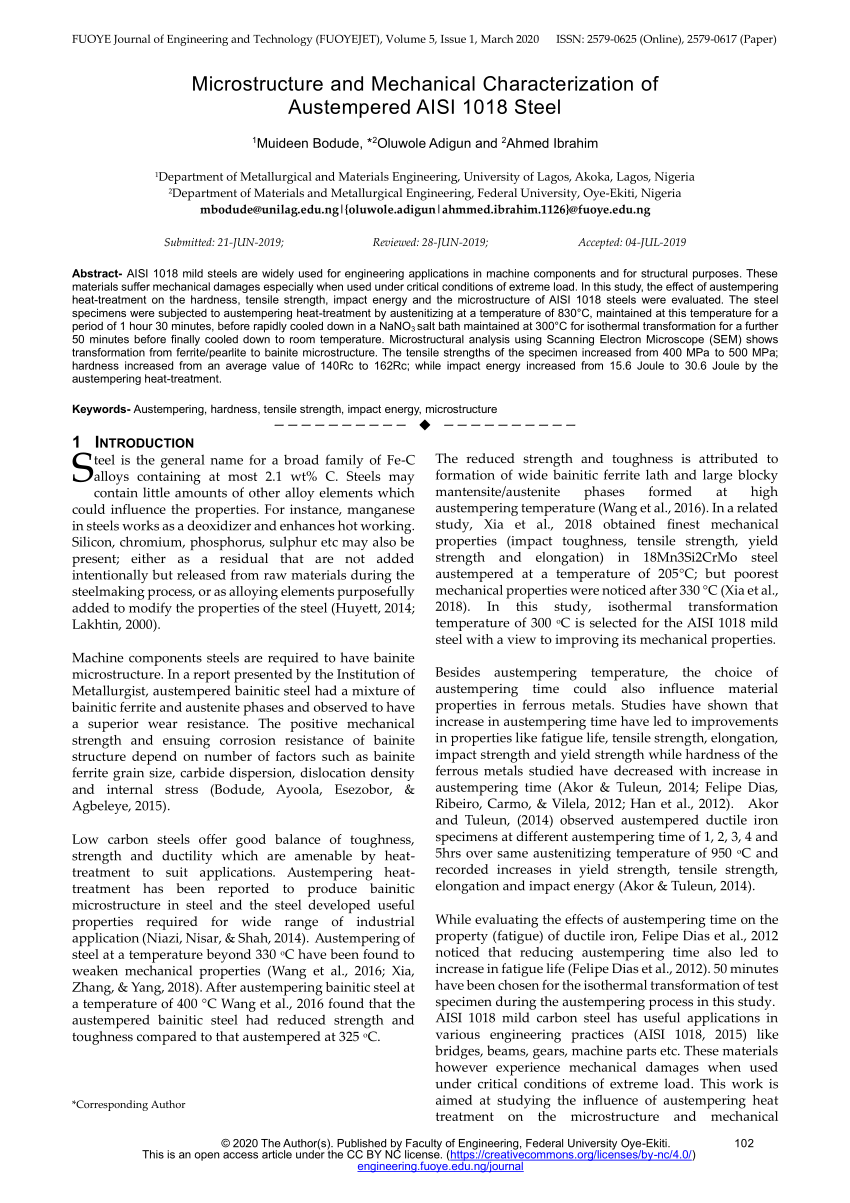

Pdf Microstructure And Mechanical Characterization Of Austempered Aisi 1018 Steel

Aisi 1018 Carbon Steel Uns G Pdf Txt

Astec Steel Medium

Iso Shear Connector Weld Stud Steel Shear Stud Building Material C1018 Buy Iso Shear Connector Weld Stud Steel Shear Stud Product On Alibaba Com

Heat Treatment Of Bolts Fasteners Purpose Of Heat Treatment Bayou City Bolt Supply

Frontiers Co2 Corrosion Of Low Carbon Steel Under The Joint Effects Of Time Temperature Salt Concentration Materials

A Study Of The Corrosion Inhibition Of Mild Steel C1018 In Co2 Saturated Brine Using Some Novel Surfactants Based On Corn Oil Topic Of Research Paper In Chemical Sciences Download Scholarly Article

Cnc Steel Material Cnc Machining Steel Fictiv

China Spheroidized Annealed Cold Drawn Chq C1018 Phosphate Lubed Fastener Low Carbon Steel Wire China Steel Coil Wire Rod

A36 Steel Plate Kloeckner Metals Corporation

2

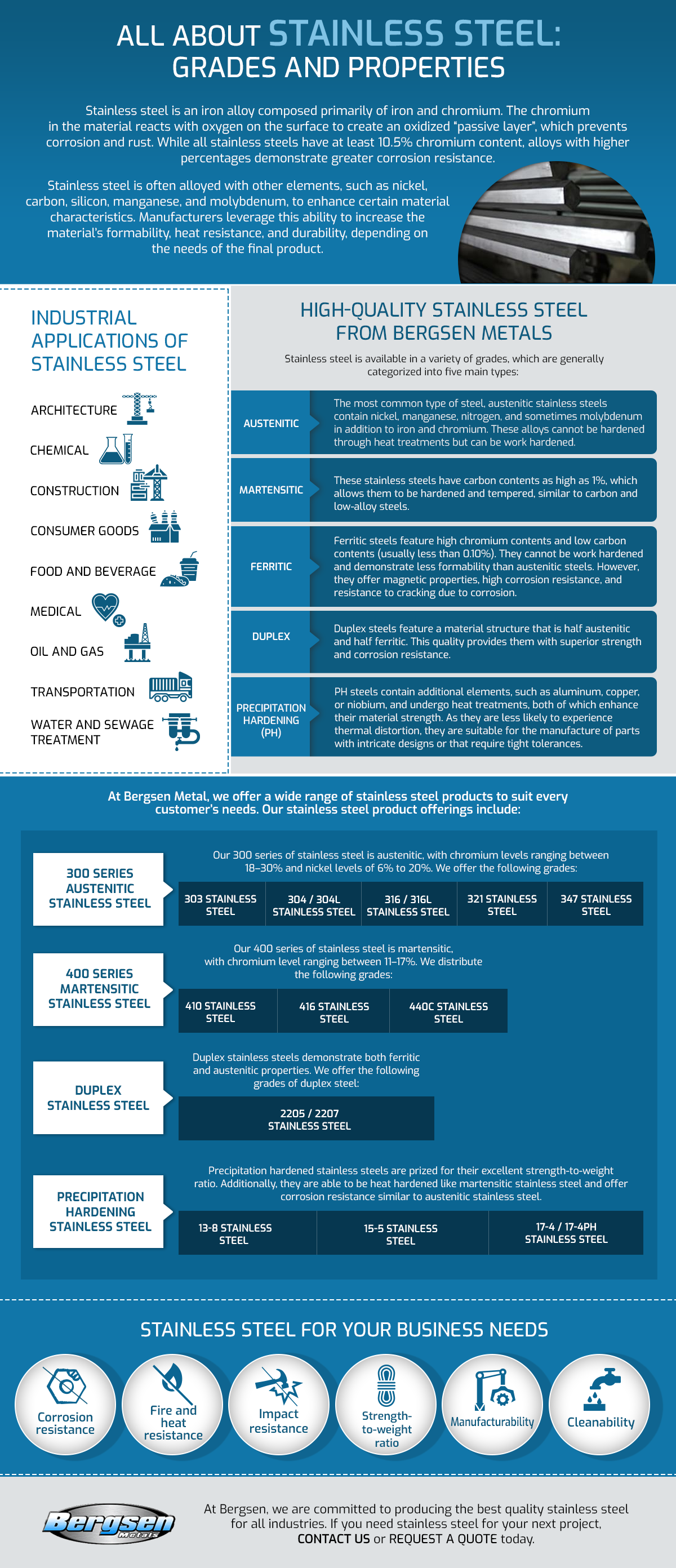

Stainless Steel Grades And Properties Bergsen Metal

What S Cold Finished Steel Bar Product

Www Osti Gov Pages Servlets Purl

Www Huyett Com Getmedia Dc0731f3 D51b 4dad f8 4302f33daf Steel Making Basics Aspx

Http Stainless Steelandtube Co Nz Wp Content Uploads 14 06 Brightcommercialmildsteelaisi1018 Pdf

Astm A36 Mild Steel Strength Of Materials

Http Eprints Whiterose Ac Uk 31 Macrh Pdf

Basic Descriptions Of Making Carbon Alloy Stainless And Tool Steel P 4 Carbon Grades Types And Numbering Systems Glossary P Pdf Free Download

Quality Cut To Size Cold Rolled Mild Steel Flat Bars Supplier In Los Angeles Ca Usa Bobco Metals

9imxvj5qhgxcem

Pdf Improvement Of The Mechanical Properties Of 1022 Carbon Steel Coil By Using The uchi Method To Optimize Spheroidized Annealing Conditions

Astm A36 Mildlow Carbon Steel Steel Strength Of Materials

2

Processing And Mechanical Properties Of Macro Polyamide Fiber Reinforced Concrete Topic Of Research Paper In Economics And Business Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

Www Osti Gov Pages Servlets Purl

2

080a15 1018 Bright Bar En3b Engineering Steel Impact Ireland Metals

China Steel Stock Sae1018 1045 1035 Polished Carbon Steel Bar Round Bar China Cold Drawn Steel Rod 1018 Steel Bar

Http Www Matweb Com Search Datasheet Pdf Quadrant Aspx Matguid 3a9cc570fbb24d119f08db22a53e2421

1018 Cold Drawn Steel Bar Supplier Cd 1018 Bar Eaton Steel Bar Company

Smooth Surface Used On Carburized Parts Astm A366 Cold Rolled Steel C1018 Buy Smooth Surface Used On Carburized Parts Astm A366 Cold Rolled Steel C1018 Roll Forming Steel Astm 66 Gr 4 Steel Flange

Effects Of Steel Fibers And Iron Filings On Thermal And Mechanical Properties Of Concrete For Energy Storage Application

Pdf Effect Of Different Quenching Media On Mechanical Properties Of Aisi 1018 Low Carbon Steel

Www Ryerson Com Media Files Resource And Reference With Ryerson Logos Mechanical Properties S2312datasteelmechanicalpropertiesbarlogo Ashx

Difference Between A36 Vs 1018 Steel Surprising Answer

7 Things To Consider When Choosing A Carbon Steel Grade

No comments:

Post a Comment